The bike ran pretty well, the rider not so great. I just couldn't get comfortable. I don't think it helped being on a circuit where after 2 laps i'd wheelied more on a motorbike than in my previous 6 years of racing.

I didnt get dyno'd/weighed, but I did put the bike on the scales in the scruit bay which are pretty accurate, it came out at 171kg with 10 litres of fuel. So i'm about 166kg with the minimum-ish amount of fuel i need for a post race dyno run and the 2 litres needed for fuel testing. I need to see what it makes on the circuit dyno, but for now i'll just run with extra fuel in the tank till i'm sure.

Few things to resolve, it seemed to be burning a very small amount of oil, but it was hard to really tell. I still have the pulsing through the brakes and they did start to fade a little. My shift lights and quick shifter don't work at high RPM, so i'm going to alter my harness and re-wire them. I'm also adding power wires for the water pump controller.

On the plus side Steve Jordan has sorted my suspension and the rear tyre wear is now much better, though Oulton isnt as hard on tyres as Brands.

Wednesday, 13 June 2012

Thursday, 10 May 2012

Another trackday in the rain

Had another track day at Brands today, it dried out for two

damp sessions then rained again all afternoon. Now I have a few things to fix, the cheap fork

seals I used seem to be leaking, not much but enough to need replacing, very annoying.

On the 2nd lap of the first session I had one of

the biggest moments on a bike that didn’t end with a crash, I clipped the

inside curb at Surtees (trying to go inside the square of messed up tarmac

there). The bike basically jumped out

under me sideways and landed on the side of the rear wheel, flipped back the

other way, slid for a bit then recovered.

The impact was so big it bent one of my chain adjusters, another thing

that needs fixing.

I’m also a bit worried that this bent my calliper bracket as

one of the bolts started rubbing on the rear disc (it only had about 0.5-1mm clearance

before).

The front brakes also pulses slightly now when i'm gently on the brakes, when i use them hard it'd fine but if i rub them or as I ease off they start pulsing. Maybe it's because I used them so much on the wet wheels first, on the plus side the SBS pads do seem much better than the stock ones I had in there before.

Anyway I still feel completely unprepared to go racing… I've never finished last in a race before, this could well happen an Oulton.

Sunday, 29 April 2012

Update

I rode the bike the other week at Brands Hatch GP, it rained all day so it was my first time on a 600 with wets. I got pretty comfortable in the end but i'm still slow in the rain. No problems burning oil this time and i didn't bin it, so overall a success. I did have trouble getting the bike up to temperature, in the end we'd taped up almost the entire radiator.

Work has continued on the water pump controller, we tested it this weekend with the pump taking water from the tap as it needs positive pressure. It needs a closed system for me to properly load test the controller so I welded up my spare radiator and will test it again during the week.

Thursday, 15 March 2012

Electric water pump

I've decided to cover the bike in vinyl rather than paint it, the seat went quite well, but the rest of it so far is quite rubbish. Still it looks a tiny bit better than it would with naked fairings.

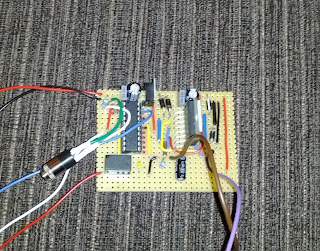

I've also decided to convert my bike to use an electric waterpump, it's hard to justify but I wanted an excuse to learn how to use microprocessors + remove the issue of overheating on a delayed grid/ after races. This should hopefully be able to keep the temperature of my bike constant, no matter the rev's or the speed i'm going.... no need to mess about with tape on the radiator when its cold either. I've written the software side, it dynamically calculates the pump speed according to how fast the temperature changes/has changed in the past. Basically it learns as you ride how it needs to control the pump to maintain a constant temperature.

This is an unfinished prototype, it's unfinished because i've managed to blow up some of the components.

I've also decided to convert my bike to use an electric waterpump, it's hard to justify but I wanted an excuse to learn how to use microprocessors + remove the issue of overheating on a delayed grid/ after races. This should hopefully be able to keep the temperature of my bike constant, no matter the rev's or the speed i'm going.... no need to mess about with tape on the radiator when its cold either. I've written the software side, it dynamically calculates the pump speed according to how fast the temperature changes/has changed in the past. Basically it learns as you ride how it needs to control the pump to maintain a constant temperature.

This is an unfinished prototype, it's unfinished because i've managed to blow up some of the components.

Sunday, 19 February 2012

Weight

I weighed my bike using normal bathroom scales, one at a time under each wheel. Not the most accurate way but gives me a good indication of the final weight. The tank was empty and the fairings weren't on (just the seat) and it came to 161.kg. One litre of fuel is about 0.7kg and I need 2 in the tank after a race in case I get fuel tested. So lets say I'll have 3 litres just to be safe: 2.1kg. I'd say 4kg is an overestimate of the fairing weight so I should be about:

161.1 + 2.1 + 4 = 167kg

With 94 bhp I need the bike to weigh 170.5kg

So i'm going to be close to optimum.

I've also decided to vinyl wrap the bike rather than paint it. I've started the seat unit, and its pretty rubbish, but i've got the hang of it now and will probably do it again once i've done the fairings.

161.1 + 2.1 + 4 = 167kg

With 94 bhp I need the bike to weigh 170.5kg

So i'm going to be close to optimum.

I've also decided to vinyl wrap the bike rather than paint it. I've started the seat unit, and its pretty rubbish, but i've got the hang of it now and will probably do it again once i've done the fairings.

Sunday, 22 January 2012

K-tech compression adjuster

Saturday, 21 January 2012

Fork rebuild

Sadly it looks like a butcher fitted the valves, and I wasn't sure if some of the damage would be a problem, a quick phone call to Steve Jordan and he confirmed they were setup correctly and the wear/damage on them wasn't an issue.

|

| Top is the standard spring, bottom is the 9.0 k-tech spring |

|

| Top is the road rebound needle, the k-tech kit has this inside the valve in the cartridge. |

|

| K-tech valves, left is the valve on the bottom of the damper rod. Right is the valve that's in the bottom of the cartridge . |

|

| K-tech valve on the left, standard on the right. |

Subscribe to:

Posts (Atom)